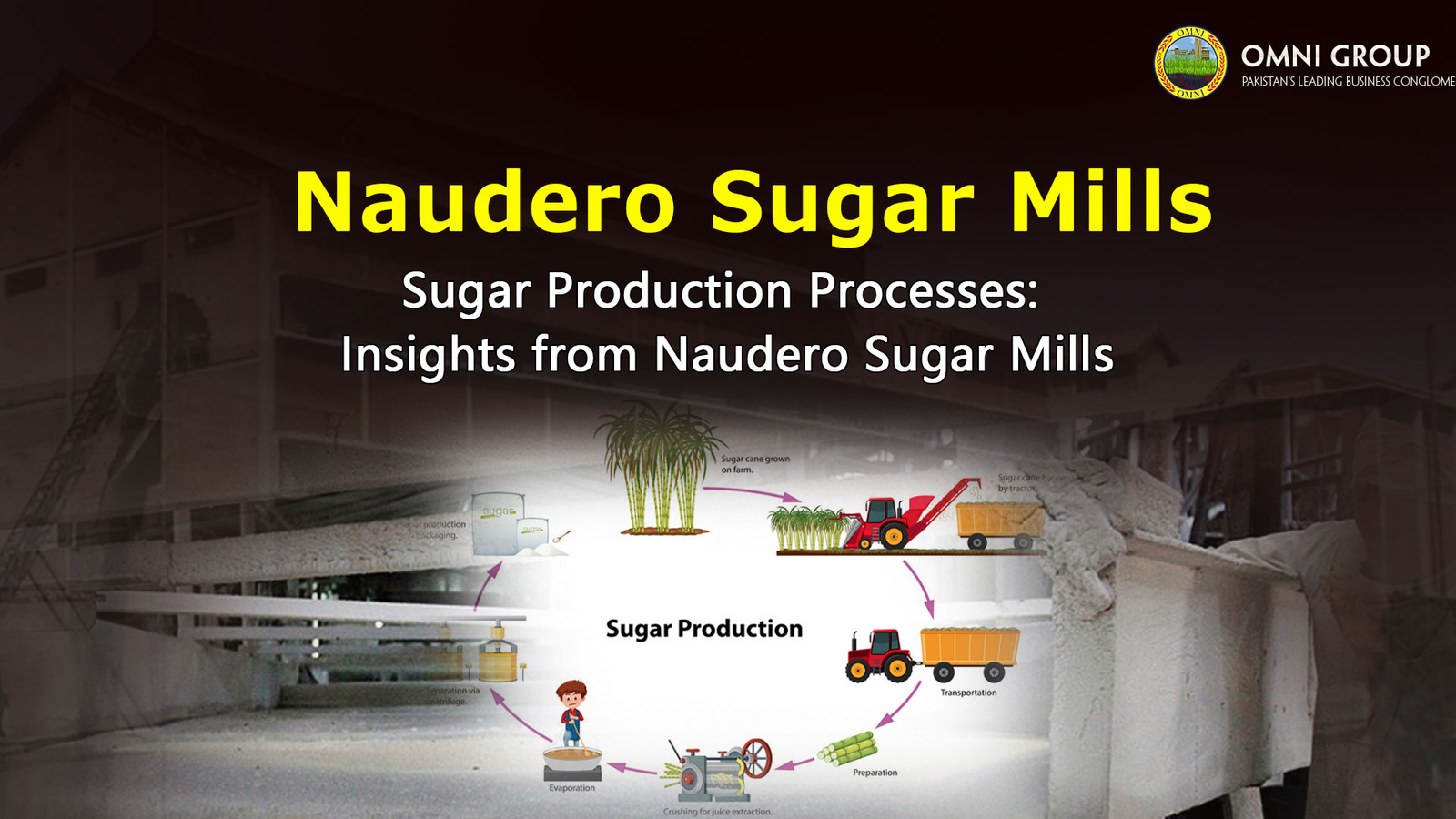

Sugar production is a complex and fascinating process that involves several stages, from harvesting sugarcane to producing refined sugar. Naudero Sugar Mills, located in Pakistan, is a prominent player in the sugar industry, known for its efficient and innovative production processes. In this article, we’ll delve into the various stages of sugar production at Naudero Sugar Mills, providing insights into their methods and technologies.

- Sugarcane Harvesting and Transport: The sugar production process begins with the harvesting of mature sugarcane. At Naudero Sugar Mills, modern harvesting equipment is used to ensure a quick and efficient harvest. Once harvested, the sugarcane is transported to the mill for processing.

- Cleaning and Crushing: Upon arrival at the mill, the sugarcane undergoes thorough cleaning to remove dirt, debris, and other impurities. It is then fed into the crushing mill, where powerful rollers extract the juice from the sugarcane fibers. This juice contains sucrose, the primary component of sugar.

- Juice Extraction and Clarification: The extracted sugarcane juice undergoes a series of processes to clarify and purify it. This includes filtration to remove solids and impurities, as well as heating to eliminate any remaining contaminants. Naudero Sugar Mills utilizes advanced clarifiers and filters to ensure high-quality juice for further processing.

- Evaporation and Crystallization: The clarified sugarcane juice is concentrated through evaporation, where water is removed to increase the sucrose concentration. This concentrated juice is then seeded with sugar crystals to initiate the crystallization process. As the syrup cools and crystallizes, sugar crystals form and separate from the liquid.

- Centrifugation and Drying: The sugar crystals are separated from the syrup using centrifugal machines, which spin at high speeds to separate the two components. The resulting raw sugar crystals are then dried to remove excess moisture, producing a dry, granular sugar product.

- Refining and Packaging: The raw sugar undergoes further processing to remove remaining impurities and achieve the desired level of purity. This refining process involves filtration, crystallization, and drying to produce refined sugar crystals. The refined sugar is then packaged into various sizes for distribution and sale.

- By-Product Utilization: Naudero Sugar Mills also focuses on utilizing by-products generated during the sugar production process. Bagasse, the fibrous residue left after crushing sugarcane, is used as a renewable energy source to power the mill operations. Additionally, molasses, a by-product of sugar refining, is used in various industries such as animal feed and ethanol production.

In conclusion, Naudero Sugar Mills employs a comprehensive and sustainable approach to sugar production, leveraging modern technologies and efficient processes. By optimizing each stage of production and utilizing by-products effectively, they contribute to the sugar industry’s growth while minimizing environmental impact.