In the heartland of sugar production, where the air is thick with the scent of molasses and the fields sway with rows of sugar cane, lies Naudero Sugar Mills. Nestled amidst the fertile lands of Pakistan, Naudero Sugar Mills stands as a testament to the meticulous process involved in transforming raw sugar cane into the crystalline sweetness that graces our tables. Today, we delve into the intricate journey of sugar processing and packaging at Naudero Sugar Mills, uncovering the meticulous steps involved in bringing this essential ingredient to consumers worldwide.

Harvesting and Milling: The journey of sugar begins in the sprawling fields surrounding Naudero Sugar Mills, where sugar cane is cultivated with care and precision. As the cane reaches optimal maturity, it is harvested by skilled workers who ensure that only the finest stalks are selected for processing. These carefully harvested stalks are then transported to the mill, where they undergo the initial stages of extraction.

Upon arrival at the mill, the sugar cane is washed and shredded to extract the juice contained within. This juice, laden with sucrose, is the raw material from which sugar is derived. Through a series of crushing, pressing, and filtering processes, the sucrose is separated from the fibrous pulp, yielding a thick, syrupy liquid known as cane juice.

Evaporation and Crystallization: The next stage in the sugar processing journey takes place in the evaporation and crystallization units of Naudero Sugar Mills. Here, the cane juice undergoes a process of concentration, where water is evaporated to increase the concentration of sucrose. This concentrated syrup is then seeded with fine sugar crystals, initiating the crystallization process.

Under carefully controlled conditions of temperature and agitation, the sugar crystals grow, gradually forming larger crystals known as raw sugar. Throughout this process, impurities are removed through filtration, ensuring that the final product is of the highest quality. Once the desired crystal size is achieved, the raw sugar is separated from the remaining syrup and subjected to further drying to remove excess moisture.

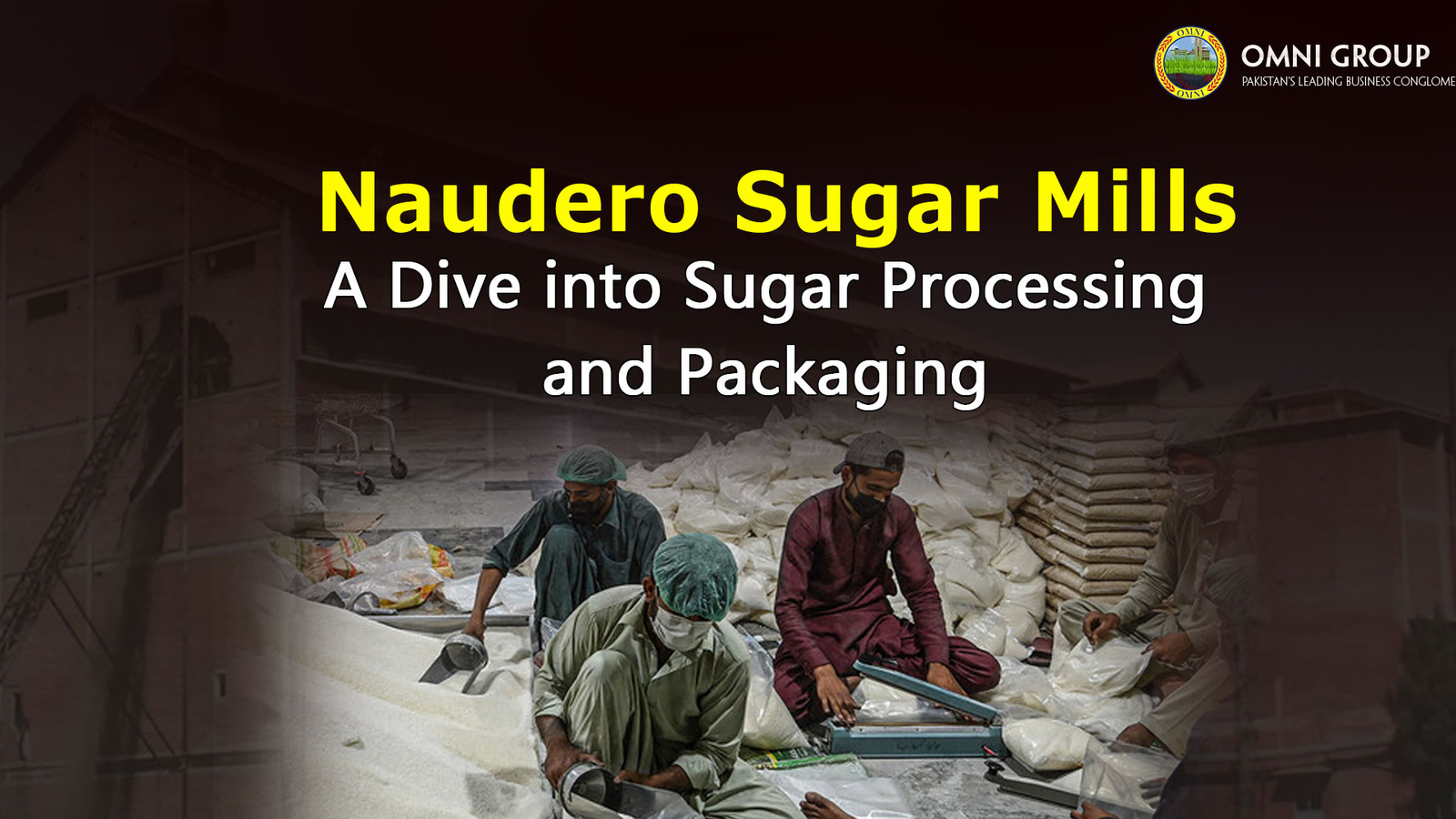

Drying and Packaging: The dried sugar crystals, now sparkling with purity, are ready for the final stage of processing: packaging. At Naudero Sugar Mills, great care is taken to ensure that the sugar is packaged in a manner that preserves its quality and freshness. Specialized equipment is employed to weigh and fill bags with the precise amount of sugar, ensuring consistency and accuracy in every package.

Before sealing, the bags are inspected for any imperfections, ensuring that only the finest sugar reaches the consumer. Once sealed, the packaged sugar is carefully stacked and prepared for distribution, destined to find its way to kitchens and tables around the world.

In conclusion the journey through the intricate process of sugar processing and packaging at Naudero Sugar Mills, we gain a newfound appreciation for the craftsmanship and dedication that goes into every grain of sugar. From the sun-drenched fields of sugar cane to the pristine packages that line store shelves, the journey of sugar is a testament to human ingenuity and perseverance. And as we savor the sweetness of this essential ingredient, let us not forget the hands and hearts behind its creation, ensuring that the world remains a little sweeter with each passing day.